Generator Services – How can we help?

SERVICING – Most generators must be serviced every 450 hours of running, or once a year, whichever comes first.

A basic service consists of all filters changed, oil changed, and coolant tested, followed by a full inspection of both the electrical and mechanical of your generating set. This ensures optimum reliability, performance, and fuel efficiency. It also gives a chance to identify any potential issues that may arise and rectify them to negate downtime in the future.

A full report is provided.

MAJOR SERVICE – A major service is all of the above with additional work conducted to check the engine valve clearances and adjust as necessary.

Correct valve adjustment not only improves performance, such as starting, smooth running, and noise reduction, it also has a dramatic effect on fuel consumption should they be out of tolerance.

Intervals vary depending on the engine manufacturer, but on average, every 2000 running hours or once a year.

BREAKDOWNS – If your generating set has broken down and you require assistance, please reach out to the number provided on the ‘’contact us’’ page.

We aim to reach you in the shortest time possible with our generator services.

LOAD TESTING – In order to ensure your generator is fit for purpose, a load bank test is the only solution.

This involves applying load to the generator in steps until 100% output has been achieved for a given time.

At this point, the performance of the engine and alternator can be clarified, and any underlying issues identified.

A full report documenting voltage, KW, amps, frequency, engine temperatures, and pressures can be provided.

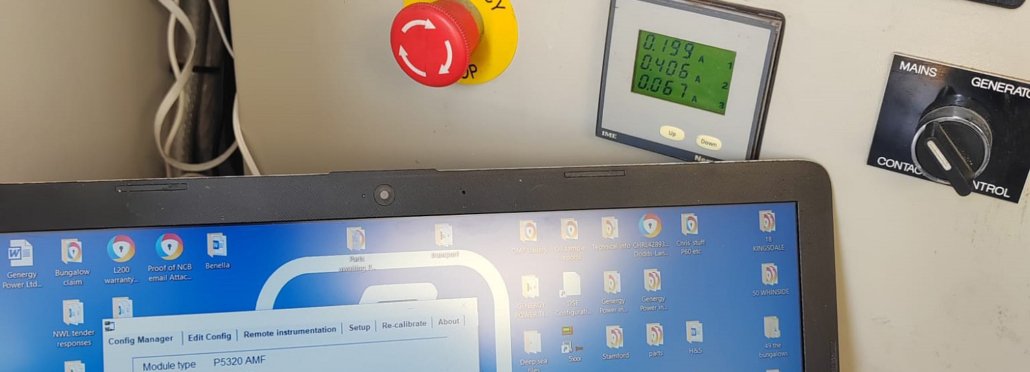

CONTROL PANEL UPGRADE – Upgrading your control panel can be a great way to enhance useability and performance, bringing your machine up to date and enabling a whole host of features to monitor safety and performance.

As part of our Generator Services, we can even install panels that allow the user to remotely access live time information from a PC or app, such as load, voltage, engine temperature, and oil pressure just to name a few.

Should the generator break down, information can be accessed, to ascertain the cause of shut down, giving the engineer a solid starting point of what might be needed before attending the site.

FUEL ANALYSIS AND TREATMENT – If you have a bulk storage fuel tank on site, you may want to consider the condition of its contents.

Fuel can, over time become subject to microbial bacteria that grow within the confines of the tank, as well as sediment buildup, this can cause a real concern if left untreated and will undoubtedly result in major problems.

Genergy Power can attend the site, sample your fuel and send it off for analysis, the results of which will determine the next steps.

Should the results be positive for microbial bacteria, we can ‘’dose’’ your fuel and retest at a later date to ensure the problem has been rectified.

If no microbial bacteria were detected but sediments were present, we can ‘’polish’’ your fuel down to 10 microns and capture any foreign bodies within your tank, this will restore the quality of your fuel making for an extremely cost-effective solution as opposed to writing off the contents of your tank.

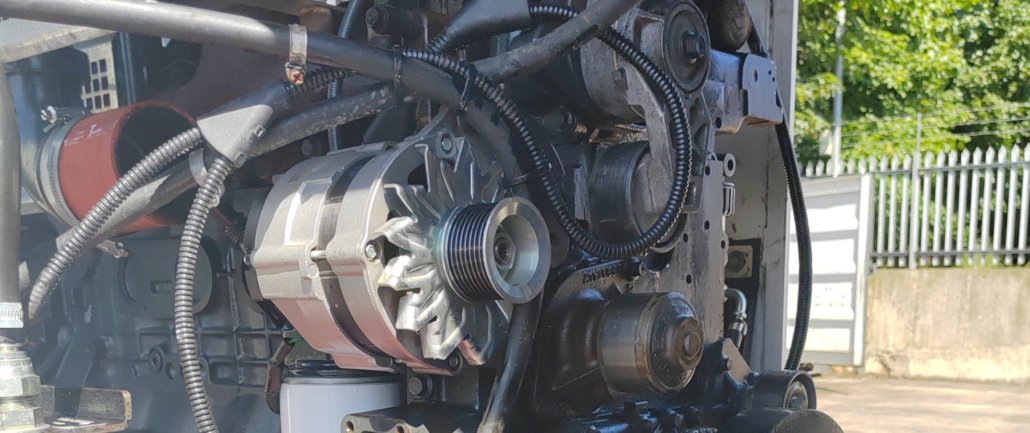

OVERHAUL AND REFURBISHMENT – We can overhaul and refurbish your generating set, including fabrication repairs and repainting of the acoustic canopy and doors.

As there are so many variables here, we discuss this on an individual basis to establish your desired outcome.